# AMB-8I

AMB-8I is a digital input extender with high voltage range from 60V AC up to 500V AC. Input also support DC voltage in same voltage range. The power supply range is 8 to 36V and accept DC or AC voltage.

# General information

| Download technical specification | [Technical Specification](https://www.atreyo.in/sites/default/files/a-download/AMB-8I%20Technical%20Specification.pdf) |

# Configuration manual

#### Features

- Configurable device address (1 ~ 255) using 8 bit DIP switch, multi devices can be cascaded on RS485 bus

- Configurable device baud rate (2400bps ~ 128000bps) using 4-bit DIP switch

- TVS (Transient Voltage Suppressor) protection, effectively suppress surge voltage and transient spike voltage in the circuit, lightning proof & anti-electrostatic

- Optocoupler isolated digital inputs, prevent interference from external high-voltage circuit

- Reverse-proof circuit, prevent the circuit from being damaged accidentally by incorrect connection

- DIN-Rail mounted plastic enclosure, easy to install, safe to use

- 3 LEDs for indicating the MCU status and signal transceiving status, also LED indication for power and inputs

- Watchdog Timer

---

#### Protocol Description

MODBUS Protocol is a messaging structure, widely used to establish master-slave communication between intelligent devices. A MODBUS message sent from a master to a slave contains the address of the slave, the 'command' (e.g. 'read register' or 'write register'), the data, and a check sum (LRC or CRC).

Since Modbus protocol is just a messaging structure, it is independent of the underlying physical layer. In AMB-4I-4O is implemented using RS485 interface.

##### Modbus RTU Framing

The AMB-4I-4O module supports standard RTU Modbus protocol for getting the input status and setting/getting the relays status. RTU Modbus Protocol frame is illustrated below:

| Start | Address | Function | Data

| RC Check | End

|

| ≥ 3.5 Char | 4 Bits | 8 Bits

| N\*8 Bits | 16 Bits | ≥ 3.5 Char |

- **Start** is at least 3.5 char time of silent interval between master and slave to start communication

- **Address** is a slave ID Address

- **Function** is the function code of MODBUS protocol

- **Data** is the appropriate data for function code

- **CRC** is Cyclic Redundancy Check for Error Checking (here, CRC-16,Big Endian(ABCD))

- **End** is at least 3.5 char time of silent interval between master and slave to start communication

##### Modbus Serial Port Parameter

| Parameter | Option/range |

| Baudrate | 9600 – 128000 configurable |

| ata bit | 8

|

| Parity | None |

| Stop bit | 1 |

##### ID Configuration of Modbus Card

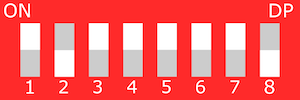

User can set the slave ID address using 8 Bit DIP switch found on board. This allow 0 to 255 different IDs to be set. The number below the switches are added together and the result will be identifier of the device slave ID.

To set the slave ID 125, you need to turn ON switch 1,3,4,5,6,7 on DIP switch and OFF the others (In this, convert slave ID number 125 into 8bit binary form – 01111101, turn ON DIP switch 1,3,4,5,6,7 and turn OFF DIP switch 2,8) and so on….

[](https://docs.atreyo.in/uploads/images/gallery/2025-03/amb-4i-4o-dip.png)

##### Baudrate Configuration

User can set the baudrate using 4 Bit DIP switch found on board. To set baudrate, first turn off power supply of card. This allows to set baudrate between 2400bps to 128000bps as shown below table.

| Baudrate | SW1 | SW2 | SW3 | SW4 |

|---|

| 9600 | OFF | OFF | OFF | OFF |

| 2400 | ON | OFF | OFF | OFF |

| 4800 | OFF | ON | OFF | OFF |

| 14400 | OFF | OFF | ON | OFF |

| 19200 | OFF | OFF | OFF | ON |

| 28800 | ON | ON | OFF | OFF |

| 38400 | OFF | ON | ON | OFF |

| 57600 | OFF | OFF | ON | ON |

| 115200 | ON | OFF | OFF | ON |

| 128000 | ON | ON | ON | ON |

---

#### Modbus RTU Commands

The following commands (functions) were implemented in the Modbus RTU AMB-4I-4O.

- 01 (01 hex) Function code – Read Coils

Coils are mapped to outputs and discrete inputs are mapped to inputs. Coils read/write output status and discrete inputs read Input status. There are 4 inputs for reading-input 0 to input 3 which refer to input 1 to input 4 and coil 0 to coil 3 which refer to output 1 to output 4.

Note: For all below example, consider slave address – 0x01 will change with 8bit DIP switch.

---

##### 01 (01 hex) Function Code – Read Coils

Read Coils command is requesting the ON/OFF status of coils. Read Coils command will return individual current outputs status. Also Read Coils Command will return sequentially outputs current status.

Example of how to read output status are given below:

REQUEST FRAME –

**01 01 0000 0008 3DCC**

**01** – The Slave Address (01 hex = 01)

**01** – The Function Code

**0000** – The Data Address of first coil to read (0000hex = coil 0)

**0008** – The total number of inputs requested (0008hex = 8 inputs)

**3DCC** – The CRC for error checking

RESPONSE FRAME –

**01 01 01 C9 91DE**

**01** – The Slave Address (01 hex = 01)

**01** – The Function Code

**01** – The number of data bytes to follow (8 inputs / 8 bits per byte = 1 byte)

**C9** – Input 0 to 7(Inputs), C9 hex = 1100 1001 (0 – ON, 1 – OFF)

**91DE** – The CRC for error checking

---

##### Modbus Exception Codes

Exception responses from either the master or a slave can result from data processing errors.

One of the following events can occur after a request from the master:

- If the slave receives the request from the master without a communication error and can handle the request correctly, it returns a normal response.

- If the slave does not receive the request from the master due to a communication error, it does not return a response. The master program eventually processes a timeout condition for the request.

- If the slave receives the request from the master but detects a communication error, it does not return a response. The master program eventually processes a timeout condition for the request.

- If the slave receives the request from the master without a communication error, but cannot handle it (for example, the request is to read a register that does not exist), the slave returns an exception response to inform the master of the nature of the error.

Exception Frame:

| Sn. | Definition | Description |

|---|

| 1 | Slave Address | The Slave Address of requested slave |

| 2 | Exception Function Code | Requested Function Code + 128 (0x80) |

| 3 | Exception Code | See in next table |

| 4 | CRC check | The CRC for error checking |

Exception Codes:

| Exception Code | Name | Description |

|---|

| 0X01 | Illegal Function Code | The function code received in the request is not an allowable action for the slave. This may be because the function code was not implemented in the unit selected. |

| 0x02 | Illegal Data Address | The data address received in the request is not an allowable address for the slave. |

| 0x03 | Illegal Data Value | A value contained in the request data field is not an allowable value for the slave. This indicates a fault in the structure of remainder of a complex request, such as that the implied length is incorrect. |

# Safety information

##### Operating environment

- The device is designed to be installed in clean, dust-free and insect-free places

- Operating temperature: -25 ~ 65°C (-13 ~ 149°F).

- Humidity range is 10% to 95% (non-condensing). Use the device in a dry environment.

- Away from heat sources and direct sunlight.

- It must not be exposed to acid fumes, salts and other chemicals.

- The device must not be used in places where there is a risk of gas explosion.

Use in inappropriate conditions may damage the device or shorten its life.

---

##### Electrical and power supply safety

- The device is powered with a voltage in the range of 8-36V. Voltage up to 24V is considered safe. Be especially careful when supplying them with higher voltages.

- Use only approved accessories

- Use the supplied power adapter or a good quality certified power adapter with the correct supply voltage range and sufficient power.

- Only use approved accessories like antenna etc.

Only a person with qualification and appropriate knowledge should install the device.

---

##### Malfunctioning and damaged device

- Do not disassemble the device.

- Only qualified personnel must service or repair the device or its accessories.

- If water or other liquid has got into the device, or if it looks mechanically damaged, do not connect the device, but take it to an authorized service center.

---

##### Radio frequency exposure

This device has been designed and manufactured not to exceed radio frequency energy emission limits set by regulatory agencies. To comply with RF exposure guidelines, the device must be used at least 20 cm away from a person's body. Failure to follow these instructions may result in exceeding the applicable RF exposure limits. This only applies to models with a built-in LTE modem.

---

##### What to do and what not to do

- You are solely responsible for the use of the device and any consequences of its use.

- Do not store or use the device in harsh environments such as dust, gases, oils, chemical vapors and damp places.

- Do not throw the device and its accessories. Handle with care.

- The device heats up during operation. Ensure proper ventilation.

- If you need to dispose of your device, check your local regulations for recycling and disposal of electronics.

- Route power, Ethernet, and antenna cables properly so that they cannot be accidentally pulled out.

- The device should be used and kept away from small children.